Project cargo and heavy lift: securing the cargo on the ship

We plan the cargo securing for your sea transports of project cargo and heavy lift cargo in compliance with international codes and standards. This plan is then used by our experienced and qualified team to supervise and ensure the implementation of various processes before and during cargo securing on the ship. We check the lashing and welding work thoroughly to ensure that it has been carried out in a satisfactory manner. When the project- and heavy lift cargo has been properly secured on the ship, we certify the securing of the cargo by means of a certificate. This certificate serves as a guarantee for your cargo and insurance.

What is project- and heavy lift cargo in sea freight transport?

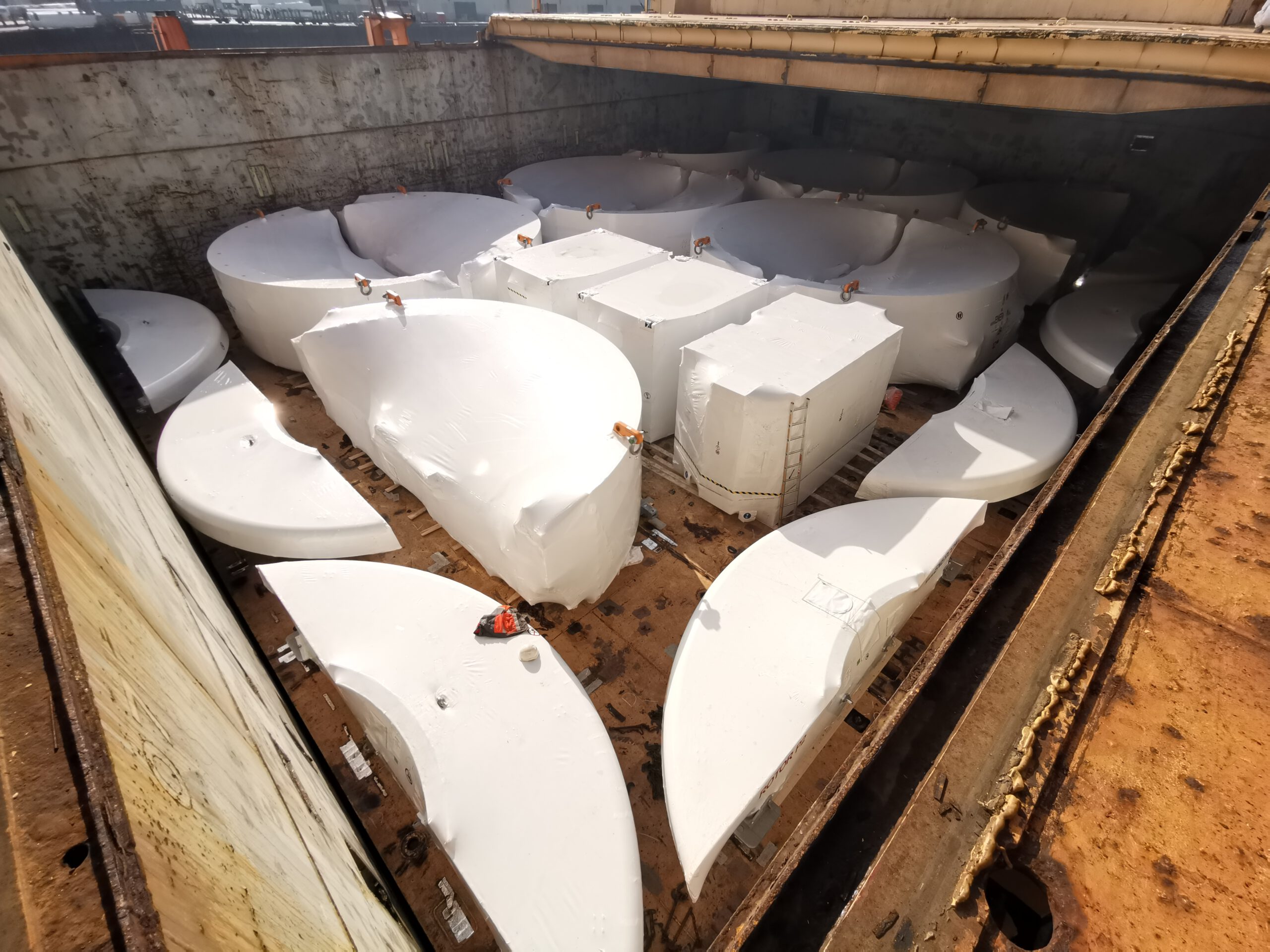

This kind of cargo can be items that do not have standardised packing dimensions. Project- and heavy lift cargoes are usually extraordinarily long, wide, high and/or heavy. Such cargo parts are, for example, components from mechanical and plant engineering, the offshore industry, the oil and gas industry, the renewable energy sector and other industries in which it is necessary to ship large and heavy cargo units. Because such cargo items do not fit into containers, they are loaded individually onto the ship and have to be considered and secured on a case or project basis.

How Hanse Survey plans and executes your cargo protection

The Code of Safe Practice for Cargo Stowage and Securing (CSS Code) of the International Maritime Organization (IMO) serves as the basis for securing project- and heavy lift cargo on vessels. This standard provides rules for the proper stowage and securing of cargo during transport by ocean-going vessels.

On the basis of the centre of gravity and other geometrical cargo data, we plan the lashing of the project cargo in a special software, which works according to the specifications of the IMO CSS Code. Depending on the ship and its determined initial stability, the expected accelerations that will influence the cargo are determined. These accelerations are based on bad weather conditions in heavy seas with high waves and hurricane-like wind forces (winter North Atlantic).

Why the correct stowage is so important

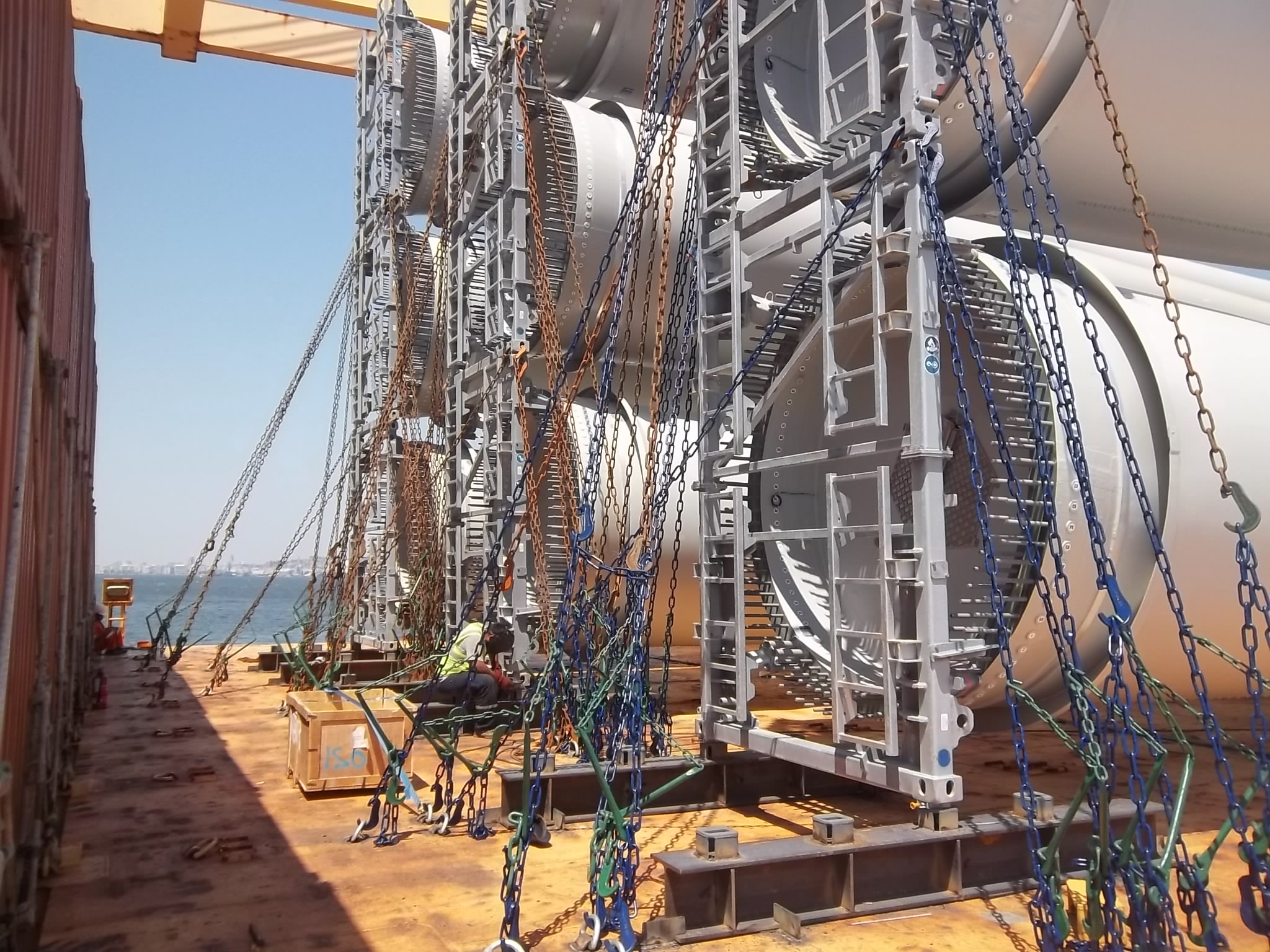

The position, where the project cargo is located on the vessel, also affects the external forces on the cargo. Consequently, this position is an important aspect which we take into account accordingly when creating the stowage plan. If project cargo or heavy cargo is to be transported on the weather deck of a ship, additional criteria must be taken into account when securing the cargo. In contrast to a closed cargo hold, cargo units loaded on the weather deck are exposed to the effects of wind and sea impacts. To reduce the risk of cargo damage or loss, these influencing factors are considered accordingly.

Once stowage planning has been completed and appropriate accelerations have been determined, we select suitable means of securing and bedding the project cargo. In the bedding – where the project cargo is placed on – we not only take friction-enhancing factors into account, but also aspects relating to load distribution and initiation. Project cargo can be bedded on a wide variety of materials.

With stowage comes the lashing concept

Lashings keep the project cargo, even in bad weather, in place on the ship. These lashings are attached to the specified lashing points of the cargo and the ship. Other lashing materials such as steel plates or beams are welded directly to the ships structure. When choosing the selection, number and distribution of the lashing materials various considerations have to be taken into account. For example, when selecting a lashing chain, not only the length and angle of the chain are accounted for, but also its elasticity and its corresponding safety factors. By planning the cargo securing, a concept is created which is executed during the securing process on board. All these measures serve to protect the project cargo from sliding and tipping during the sea voyage.

Supervising the cargo securing

Before and during the actual cargo securing work, we supervise the various processes on board the ship and ensure that the previously prepared concept is followed accordingly. For this purpose, we determine the positions of the selected materials (e.g. stopper plates or D-rings) on the ship. It should be noted that not every area of a ship is suitable for attaching cargo securing. The (local) ship’s structure and its “no welding areas” have to be considered. In the case of welding work, we pay particular attention to safety on board and the prevention of damage to cargo (e.g., through flying sparks). When securing project cargo and heavy-lift cargo onboard a vessel, several parties usually work together. In addition to the ship’s command and crew, these parties are the welders and the so-called lashers (i.e., personnel who attach tension chains, lashing straps, etc. to the cargo). Before the loading begins, we instruct all relevant parties. Effective and proper cargo securing can always be attributed to successful teamwork.

Checking the cargo securing

During the inspections, we check that the cargo securing meets the specifications. If any errors are found they are communicated accordingly, then rectified and checked again, until the cargo has been secured properly and professionally. Welding seams are visually inspected for quality. The condition and pretension of chains and lashing straps is inspected. As usually many cargo units are loaded and secured, large quantities of chains, lashing straps and stopper plates have to be checked during or after loading. For this reason, the inspection of cargo securing is a continuous process.

Certification of the cargo securing

Satisfactory cargo securing is achieved as soon as the relevant requirements according to the IMO CSS Code are met. As a guarantee, we issue a Safety- and Securing Certificate, which certifies that the cargo securing for your individual sea transport is ensured under consideration of the determined values (e.g. ship stability).

Finally, we summarise all relevant data and facts concerning the cargo securing in a separate report (Lashing and Securing Survey Report). This contains descriptions and assessments of the cargo securing, a time sheet of the loading/securing work, as well as relevant photographs illustrating and documenting the cargo loading and securing. Upon request, the report may contain additional individual information (e.g. conclusions derived from our observations and recommendations for future cargo operations).

Are you planning a sea freight transport of project cargo? Contact us, we will be happy to advise you.