Barge Survey – your pontoon towage in safe hands.

Are you planning to transport extraordinarily large and heavy cargo items on a pontoon? Then Hanse Survey is exactly the right contact for you. Our competent team of experts from the shipping industry will accompany your pontoon transport from the evaluation and planning to the execution of the transport. In doing so, we constantly ensure compliance with the applicable internationally recognised codes and standards. Through numerous supervised barge transports, our experts for heavy-lift cargo can draw on a wealth of experience in the field of sea transports of cargoes up to 1000 tonnes individual mass.

What is a pontoon (barge) and what are the advantages?

A pontoon, also known as a barge, is a rectangular floating vessel that has no propulsion of its own and is therefore set in motion by means of a tugboat. Due to its construction, a barge can have a low draught. Therefore, areas with particularly shallow waters can also be reached. Another advantage of a barge is that its flush cargo deck often has a particularly high strength, which makes it possible to transport exceptionally heavy and large cargo. Our experts will be happy to advise you and plan your next barge transport.

Definition of a barge survey

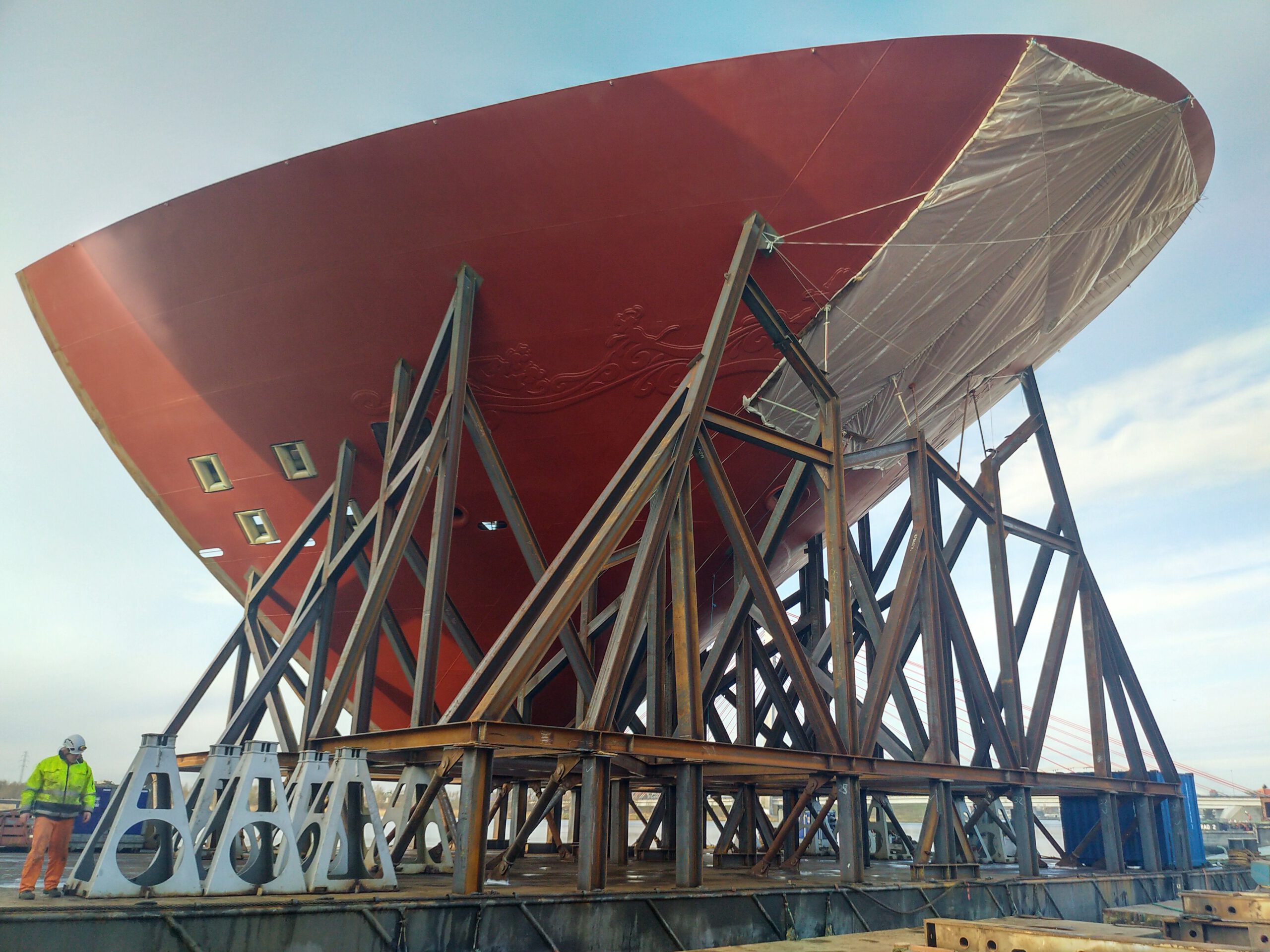

Hanse Survey ensures that the cargo is safely stowed and secured on the barge so that nothing stands in the way of shipping by tugboat to the destination. For this purpose, we support you in the planning phase and subsequently supervise the loading on site. Due to their size, unusual shape or weight, some project cargo cannot be transported on standard general cargo vessels. Examples of such cargo types can be ship hull sections, oversized cranes and similar cargoes that are difficult to transport in individual parts. For these special cases, there is the possibility of transporting the cargo on a pontoon by means of sea towage. A barge survey aims to ensure that project cargo is properly loaded on the pontoon and secured in accordance with recognised guidelines. In addition, we check the arrangement of the entire tow (e.g. towing gear, emergency towing wires, etc.), taking into account relevant codes and standards for the voyage to be undertaken.

Which codes and standards are applied?

In order to guarantee a safe process of a barge transport, Hanse Survey works according to internationally recognised and practice-proven specifications and guidelines:

We use the Code of Safe Practice for Cargo Stowage and Securing (IMO CSS Code Annex 13) from the International Maritime Organization as the first basis for assessing the securing of project cargo and heavy lift for pontoon transports. In addition, we use the standard “Marine Operations and Marine Warranty” (DNV-ST-N001) published by the classification society DNV, which has been setting the standards for marine towage for over 50 years. This standard contains industry best practices, numerous calculation methods, risk assessments and guidelines for technical documentation for barge surveys.

The Hanse Survey experts complement these codes and standards with their extensive experience in the field of barge transports and sea towage.

The planning phase for pontoon transports

In the preparations for a planned sea towage, we examine the transport for various aspects at your request. These include, among others, transport accelerations, load determination and stresses of the pontoon deck structure, strength analyses, conceptual design of cargo securing, preparation of stowage plans, construction of transport frames, evaluation of pontoon intact stability, as well as selection and suitability of the towing arrangement; – taking into account the upcoming sea voyage. We play a role in clear and goal-oriented communication with the parties involved in the planning phase and execution of pontoon transports.

The loading operation – How heavy and large cargo items get onto a pontoon

Before the loading work begins, a tool box meeting is held on site. Here, the parties involved are briefed on the upcoming operational steps before loading begins:

Loading by crane

In most cases, cargo items are loaded with a crane. This can be different types of cranes such as gantry cranes or mobile harbour cranes, which lift the cargo part alone or together in combination. For this purpose, the crane hook and the load part must be connected to each other, wich is done by means of lifting gear (e.g. cross beams, wire ropes, shackles). The selection of the lifting equipment should meet the technical-legal requirements of the upcoming lifting operation. The design and combination of crane and lifting equipment depends largely on the items centre of gravity, geometry and weight of the load. Attachment points for connecting the load to the lifting equipment are not always freely selectable. Talk to us! We will be happy to assist you in planning your next crane loading.

Loading by SPMT

In recent years, pontoon towing has increasingly seen the loading of heavy cargo parts onto pontoons with the help of heavy-duty transport vehicles, so-called SPMTs (Self-Propelled Modular Transporters). Here, a Power Pack Unit (PPU) drives a vehicle with a platform. The PPU supplies the hydrostatically driven SPMT with pressurised oil for driving, steering and lifting. This allows the platform, which is coupled with a number of adjustable axle wheels, to lift the load and move it. Thus, the heavy load transport vehicle can drive the load up and down the pontoon (Roll-On Roll-Off / RoRo). When transporting particularly large loads, it may be necessary to couple several SPMTs together.

Loading by skidding

A decrease in the use of means for loading heavy cargo on pontoons can be seen in the use of rail systems for skidding the cargo and hydraulic ram systems for lifting the cargo. This method is used especially for ship section transports, as such sections are built in the shipyards from the beginning on corresponding rails close to the pier edge. After completion of a section, further rails are coupled to the existing ones and positioned on supports for load distribution on the pontoon. During the shifting process, a ship’s section is supported on the rails either by trolleys or lubricated bearing pads (e.g. Teflon). Hydraulic cylinders, which are connected to both rail and section, allowing a controlled push of the section, over the rail system onto the pontoon. After the section has arrived at its intended final position on the pontoon, it is lifted off the rails by means of hydraulically driven jacks and set down on support trestles.

Stability assessment and ballast planning

Regardless of the loading method, the pontoon’s intact stability criteria must always be checked. Due to the cargo weight, the pontoon gets a different floatation position, which is readjusted to the required position by means of ballast water in the ballast tanks. In the case of SPMT or skidding loading, there is an additional aspect because the cargo mass is loaded horizontally onto the pontoon and at the same time the pontoon has to maintain an upright and straight floating position. In addition, the loading height (vertical distance from the pontoon deck to the quay edge in the loading area on land) should not change significantly. For this procedure, ballast water is pumped into/out of the various ballast tanks of the pontoon. In the planning phase we work with a specially developed stability software. Hanse Survey has already planned and supervised numerous pontoon shipments with regard to stability and ballast planning. We also have experience in the area of complex tidal loading and can advise you. Do you need a feasibility study for your next pontoon transport? Contact us, we will be happy to assist.

Securing the load – welding and lashing work to secure the cargo unit

When selecting the appropriate lashing arrangement, it is first of all a question of the expected cargo care during the voyage. In the case of unmanned transports, it is not advisable to use lashings that have to be checked and retightened regularly (e.g. sea voyage of several days without a stopover). Rigid securing elements (steel beams, strat braces) should be used, which are welded together with both the cargo and the pontoon deck. Considerations regarding statics and strength must be made in advance and the cargo securing concept must be designed accordingly (e.g. weld seam calculations). For sea voyages with stopovers or river voyages, securing elements with higher elasticity values can be used as an alternative. These include, for example, chains or wires which are attached to the lashing points of the cargo and pontoon (e.g. D-Rings). However, these securing elements require regular checking and retightening by the crew of the tow or pushed convoy. Contact us, we will be happy to advise you on the conception of a proper and cost-efficient cargo securing.

Towing Approval – The Insurance Guarantee for Your Cargo

As shipping experts, we see it as our task to compile and check the necessary requirements, e.g. certificates for lifting gear, welding personnel, lashing material, lifting equipment, towing gear, etc.). We also carry out plausibility checks of requested calculations, e.g. strength analyses or lashing plans, and check the conformity of the work carried out. Particular attention is paid to the welding work, which is inspected by our trained personnel. All these measures serve to secure a pontoon transport and thus create a legal framework. As a guarantee for the insurance, we hand over the following certificates to the client:

The towage certificate serves as proof of a proper tow or pushed convoy and, if necessary, imposes restrictions with regard to external influences, e.g. sea and wind limits.

Hanse Survey has created the basis for successful and cost-efficient insurance in a large number of pontoon transports and is also an expert in complex cases such as heavy and large cargo parts and tidal loading. Visit us in our Office. We will insure your next pontoon transport.